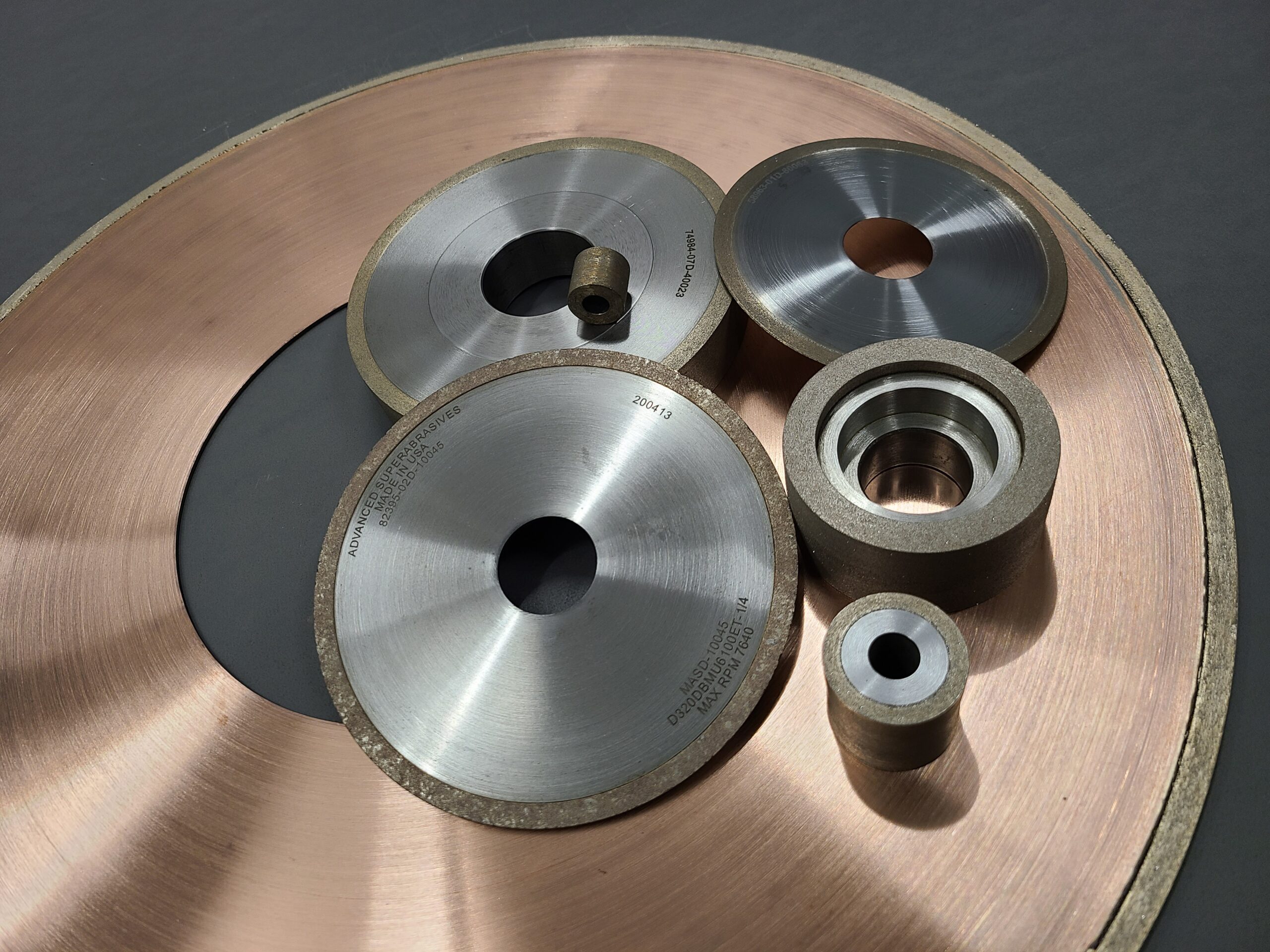

A diamond rotary dresser is a specialized tool used in grinding and machining operations to improve the surface finish of a workpiece. It is composed of a diamond-tipped rotating head that is held in place by a clamping mechanism. The diamond tip is designed to grind away any imperfections or roughness on the surface of the material being worked on.

The diamond spinning dresser is typically used to sharpen cutting tools, deburr parts, and to create a smooth finish on a part’s surface. It works by using a high-speed rotating head with diamond tips to grind away any surface imperfections. The diamond tip is extremely hard and can be used to remove even the toughest materials from the workpiece.

The dresser can be used on many different materials such as metals, plastics, ceramics, and even glass. It is an important tool in the machining industry because it allows for better surface finishes and tolerance control. It can also be used to clean up part surfaces, polish edges, and to create a desired finish.

Overall, a diamond rotary dresser is an essential tool for any machining or grinding operation. It is capable of providing a superior finish and can help improve the accuracy and precision of the finished parts.